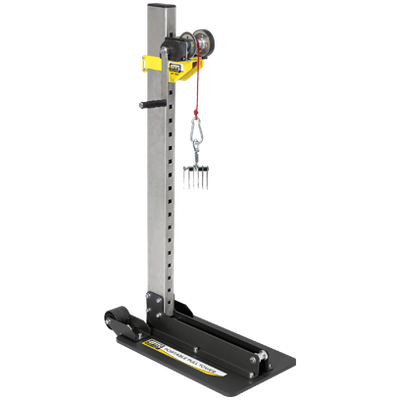

Speed Key Loader for MAXI

VIDEO: Coming Soon!

Description

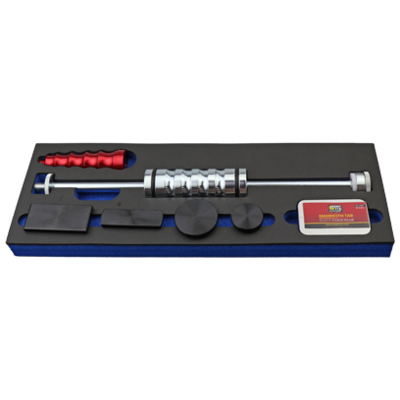

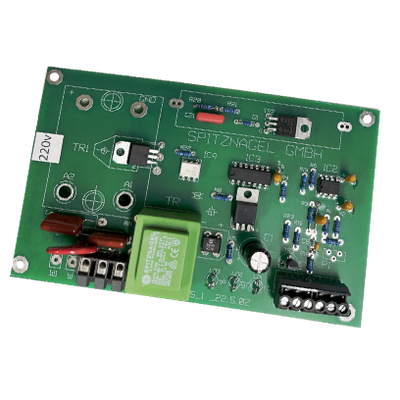

The DF-503WKSL Welding Key Speed Loader streamlines the welding of key tabs during dent repair operations. Featuring a spring-actuated delivery mechanism, this tool enables quick and consistent welding of repair keys with minimal effort. Designed for seamless integration with all MAXI Steel Dent Repair Station configurations, it enhances workflow efficiency in professional body shop environments. Built for durability and consistent performance, the DF-503WKSL integrates seamlessly into any high volume body shop workflow.

Application

The Welding Key Speed Loader is specifically designed for use in:

Collision repair facilities performing steel panel dent corrections.

Auto body shops utilizing weld key repair techniques

Insurance repair operations demanding fast turnaround times

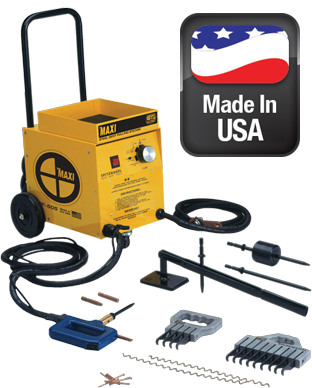

Compatible with all MAXI Steel Dent Repair Station models, this tool is ideal for technicians who perform high-volume dent repairs and need to maximize efficiency without sacrificing quality.

Feature & Benefits

Spring-Actuated Delivery System: Automatically feeds keys for instant availability. Reduces hand fatigue during extended repair sessions. Eliminates dropped or misplaced keys

Universal Compatibility: Works with all MAXI Steel Dent Repair Station configurations. No modifications or adapters required. Integrates into existing workflows immediately

Enhanced Workflow Efficiency: Reduces key positioning time by up to 60%. Maintains consistent key placement for reliable welds. Allows technicians to work with one continuous motion

Ergonomic Design: Lightweight construction minimizes operator strain. Intuitive operation requires minimal training. Comfortable grip for all-day use.

Professional-Grade Construction: Built to withstand demanding shop environments. Durable materials ensure long service life. Minimal maintenance requirements.

Includes

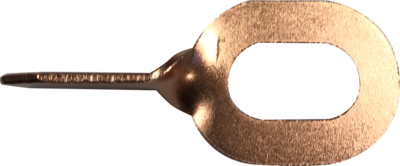

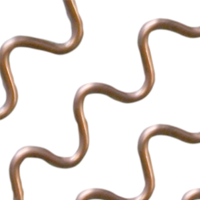

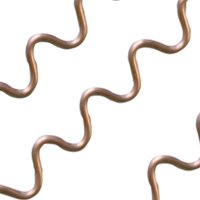

Speed Loader and Sample of 20 Flat Style Weld Keys.

Specifications

Spring-loaded mechanism for rapid key deployment

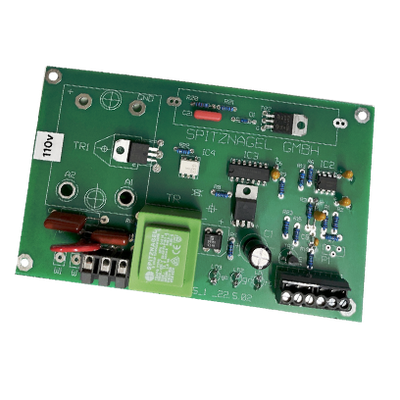

Compatible with all MAXI Steel Dent Repair Station models

Ergonomic design reduces technician fatigue

Includes 20 copper-coated welding keys.

Storage

Not Included.

Downloads (Flyer)

Coming Soon!

Operation

The Welding Key Speed Loader is designed for simple, intuitive operation that integrates seamlessly into your dent repair workflow. Follow these steps for optimal performance:

Step-by-Step Operation:

1. Load the Keys

- Open the loading chamber of the DF-503WKSL

- Insert copper-coated welding keys into the magazine

- Close the chamber securely – the spring mechanism will engage automatically

2. Position the Tool

- Hold the Speed Loader in your dominant hand with a comfortable grip

- Align the delivery tip over the dent area where the key tab needs to be welded

- Ensure the surface is clean and free of paint or debris for proper welding

3. Deploy the Key

- Press the release trigger or button to activate the spring mechanism

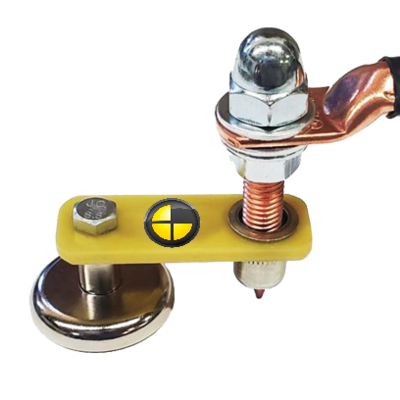

- The tool will automatically advance and position a single key at the welding point

- The key will be held securely in place, ready for welding

4. Weld the Key

- Using your MAXI Steel Dent Repair Station, apply the welding electrode to the positioned key

- Complete the weld according to your standard welding procedure

- The spring loader maintains key stability throughout the welding process

5. Repeat as Needed

- Once welded, move to the next repair location

- The Speed Loader automatically advances the next key into position

- Continue the process until all necessary keys are welded to the repair area

6. Perform Dent Pulling

- Proceed with your standard dent pulling technique using the welded keys

- Remove keys after repair completion following normal procedures

Tips for Best Results:

- Keep the tool perpendicular to the work surface for consistent key placement

- Reload keys before starting large repair jobs to avoid interruptions

- Clean the delivery tip regularly to prevent copper residue buildup

- Store in a dry location to maintain spring mechanism integrity

- The entire process takes seconds per key, dramatically reducing setup time compared to manual key placement methods.